Custom Software Development

We develop tailored software solutions for safety-critical systems and shorten time-to-market through AI-supported processes.

OFFERING:

Software development for everything from small devices to multi-user ASIL D series ECUs

CUSTOMER:

OEM | Tier 1 | technology-oriented start-ups

PORTFOLIO:

- Small control units (HW/SW) for specialized customer applications

- Platform software for large-scale production

- Architecture, system integration, and consulting

- Development of toolchains

Precise software solutions for safety-critical and highly complex systems – from advanced development to series production. We combine deep domain expertise with state-of-the-art development processes that are specifically enhanced and optimized through AI components, enabling us to significantly reduce our customers’ time-to-market.

Our portfolio includes embedded software for all types of ECUs, ADAS/AD functions, cloud backends for processing measurement data, and AI-supported systems. Through rapid prototyping and virtual validation, we can secure functional scopes early in the project cycle and minimize development risks. We work in accordance with the highest industry standards, such as ASPICE Level 2, ISO 26262 up to ASIL D, and ISO 21434 for cybersecurity. This ensures not only functional safety but also long-term reliability and protection against cyber threats. Our customers range from global OEMs and Tier-1 suppliers to dynamic start-ups across various industries.

Whether it’s integrating complex systems, developing new functions, or optimizing existing platforms — we support our customers throughout the entire development process, understand their needs, create solutions, and deliver high-performance, safe, and future-oriented software products.

Our reference projects

The following examples showcase a selection of developments that highlight our special expertise in combining software architecture, system integration, and safety-critical automotive technology. Each solution reflects our ambition to translate complex requirements into precise, efficient, and future-proof products.

01 Electronic Chassis Control

The use of software in the chassis domain is subject to particularly high demands. It must operate reliably and safely without allowing individual components to interfere with each other. A key role is played by the control unit, which deterministically allocates computing time and continuously monitors the executed software functions.

A standards-compliant AUTOSAR basic software stack was developed that ensures functional safety while enabling flexible development processes. It allows partial flashing of software states—independently of other components’ release cycles—which is a decisive advantage during field testing and validation phases.

The core element is a partitioned RTE that is fully compatible with the AUTOSAR standard and, in accordance with relevant safety regulations, ensures strict encapsulation of software components.

Coordinating communication among more than a dozen involved parties was a regular part of the project scope. We unified and aligned the RTE interfaces and coordinated integration between the automotive manufacturer and the ECU supplier. Thanks to our experience in both areas—OEM functional architecture and ECU development—we were able to precisely reconcile requirements and deliver a robust, standards-compliant solution.

The result is a software platform that can be tested flexibly in the field and operated reliably in series production—with clearly defined interfaces and a high degree of interoperability.

02 Fail-Op Power Electronics

A high-performance platform was developed for controlling brushless synchronous machines, supporting both speed and position control. The focus lies on the development and integration of control algorithms that enable precise, dynamic, and safe actuation.

The solution is based on a foundational system software, supplemented by the integration and extension of motor drivers using Clarke and Park transformations. In addition, drivers for various sensor concepts—such as incremental encoders and resolvers—were implemented to ensure high flexibility when integrating different hardware components.

A key component is the software for the position and speed controllers, which ensures excellent control accuracy combined with high robustness. The platform is successfully used in advanced development projects for controlling vertical systems and provides a solid foundation for further applications in the field of electric drive technology.

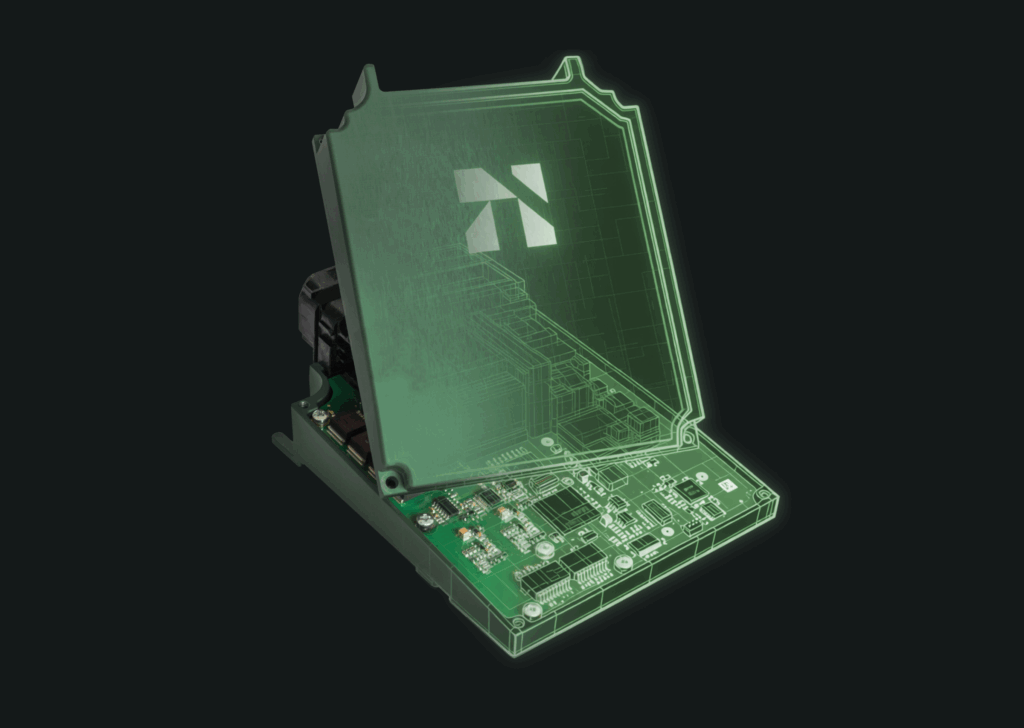

03 OBD Diagnostic Adapter

The development of the UDS Whisperer diagnostic adapter is based on our experience in safety-critical embedded software, vehicle communication, and diagnostic systems. We combine deep expertise in embedded software, UDS, and diagnostic communication with strong capabilities in system architecture, hardware design, and backend integration.

Our teams develop both ECU software as well as diagnostic tools and cloud integrations—from microcontroller-level implementations to backend data processing. With this end-to-end expertise, we can design and efficiently implement complex communication and update processes in a holistic manner.

The UDS Whisperer was created from the ambition to translate this experience into a compact, flexible product that demonstrates how intelligent software and system integration can accelerate development, testing, and fleet processes.

04 Powertrain Control

As part of a project for the driving dynamics control of an electric super sports car, an existing series-production ECU was equipped with our own software and extended for use in production vehicles. Customer-supplied control software was integrated and embedded into a safety solution we developed specifically for this purpose, optimally tailored to the existing hardware architecture.

The implementation was based on an AUTOSAR-compliant software architecture with ASIL-C requirements within an ASIL-D–classified drivetrain system. This ensured functional safety, deterministic task scheduling, and robust communication throughout the system.

Development took place within an ISO-9000–certified process, including system design, implementation, integration, and vehicle testing. The result was a fully production-ready small-series implementation that met existing OEM standards while demonstrating how complex safety requirements can be efficiently realized on production hardware.